Everyone likes new tools right? Well, my eye caught some neat pogo probes posted on the Adafruit Industries Blog a few months back, and was intrigued. I wanted a pair, but I shied away from the short handles. Then, a few days ago, it happened. I was cleaning out one of my toolboxes, and voila! I found a pair of old probes with bent tips, perfect for making into pogo probes. I also had some pogo pins from Adafruit laying around, waiting to be used for something besides having breadboard wars with ‘micro spears’. Anyway, here is how I made them with a few pictures. You will need an old pair of meter probes, pogo pins, a small hand drill, a Dremel with a cut off wheel (a steel hacksaw will also work), a vice, heat shrink, and a few ounces of patience for this project.

*Just a side note: the vice used in these pictures is a PanaVice Jr. I got mine from Adafruit Industries. I did not want to mount mine to my bench permanently, so I filled the base solid with lead. It is awesome, if you don’t have one, get one. It will change your life. (Actual life changing experience may vary.)

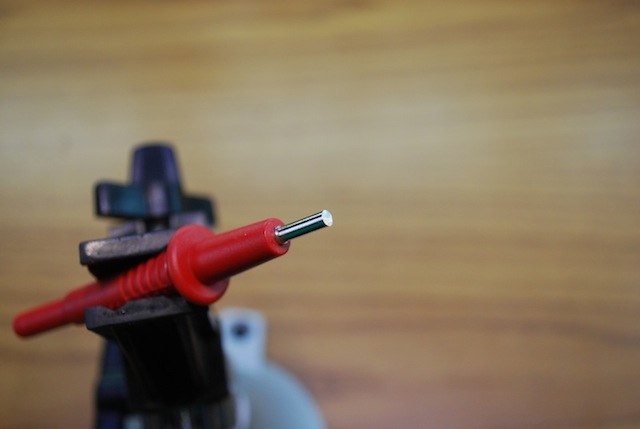

Step 1: Select a probe to convert. It doesn’t matter if the end is bent as it will be cut off anyway.

Step 2: Remove the banana plug spring from the probe with a small pair of needle nose pliers.

Step 3: Cut off the tup of the probe with a Dremel equipped with a cut of wheel.

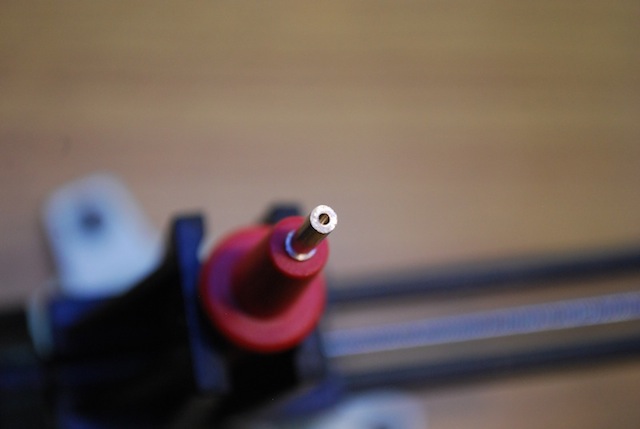

Step 4: Measure the pogo pins. The pogo pins from Adafruit measured .0405″.

Step 5: Get your drill set ready! For this project I would drill by hand, drill bits this size tend to break really easy, and you don’t want to break one off in a probe..

Step 6: Measure the drill bit to be used, this one was .0465″, .006″ larger than the pogo pins. You don’t want to make the hole too big, as it will be hard to solder it in straight.

Step 7: Start your pilot hole. Be sure to keep the bit in line with probe, not drilling at an angle. Start with light pressure and let the bit do the work. It is important to have this hole centered.

Step 8: Check the pilot hole to ensure you are heading down the right path. Once you are sure the pilot hole is centered, start drilling!

Step 9: When drilling your hole, be sure and clean it of metal shavings often by turning upside down and giving it a few taps. I drilled these holes about .25″ deep.

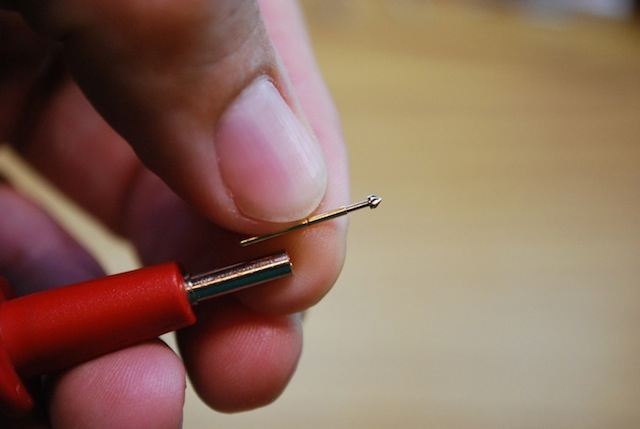

Step 10: Test fit the pogo pin in the probe.

Step 11: This is approximately the depth I drilled the hole in the probe. Drilling time was about 10 minutes per probe.

Step 12: Solder the pogo pin in the probe, making sure you give a good amount of heat. I did ~336˚C for about 20 seconds.

Step 13: Note to self: DON’T DROP THESE ON HARDWOOD FLOORS! This step earned me de-soldering the bent pogo pin and re-soldering a new pogo pin. Good thing I had 10 of these. 😉

Step 14: Test fit heat shrink tubing for the probe. I used a small piece as well as a larger piece to form a better fit.

Step 15: Shrink the smaller tube towards the top of the probe.

Step 16: Now shrink the larger piece of heat shrink and you’re done!

Now I have a nice(r) collection of test probes for my meter. 🙂

Pingback: Pogo Probes! « adafruit industries blog

Nice Post!

Nice!!!!

Thanks!

Pingback: Electronics-Lab.com Blog » Blog Archive » Pogo Probes!

good upgrade! I’ll have to try this out when my ones break – don’t think I’ll try hand drilling it though!